Fairfield Farms Dairy Cooling Station Detour

Milk Run Trains/Cars

- http://www.riverraisinmodels.com/libraryData/milktrains.pdf

1881 Purpose built refrigerated or insulated cars were introduced.

These hauled milk in individual standard 40 quart cans.

Attempts at bulk tanks in refrigeratd cars wee tried in 1904 and condemned for structural reasons in 1914.

1916 and 1920 proved a structurally sound concept but failed to get industry interest.

Thomas Otto of Harmony Creamery in Pittsburg convinced Pfaudler and B&O to modify existing refrigerator cars.

2,500 gallon tanks replaced ice bunkers at each end and the cars frames were reinforced.

This was successfully test run in August 1921 and displayed at the National Dairy Show in Minneapolis.

Their basic design was really fixed by Wieland Dairy experiments in 1922.

The cars had steel underframes, with passenger-type trucks, buffers and couplers.

Train steam and signal lines were installed to facilitate handling the cars in passenger consists.

Steel cradles to hold the two tanks at opposite ends of each car were riveted directly to the frame for strength.

Each tank had a 3,000-gallon capacity, and was made of seamless glass-lined steel.

- https://en.wikipedia.org/wiki/Milk_car

Once the handling advantages of a separate car were recognized, milk cars were built with insulation

to reduce warming during transit and the milk cans might be packed in ice during warm weather.

A few milk cars were built or retrofitted with mechanical refrigeration following World War II

Increased availability of motor vehicles after World War I encouraged bulk transport of milk

to minimize inefficient handling, washing and redistribution of milk cans.

A standard 46.5 US quarts milk can weighed 27 pounds and held 86 pounds of milk.

Farmers needed two sets of milk cans so one might be filled while the other was at the dairy.

Caspar Pfaudler invented a method of lining cast iron tanks with glass while working with the brewing industry.

The first glass-lined tanks were built by the Dickson Manufacturing Company in 1887;

and the Pure Food and Drug Act of 1906 increased use of these tanks for milk products.

The Boston and Maine Railroad (B&M) was using a milk car with glass-lined steel tanks in 1910.

Pfaudler designed what became a standard milk car with two 3,000-US-gallon tanks inside a closed car.

Earlier cars featured a removable roof to replace damaged tanks,

but the tanks proved durable enough to eliminate that feature from later production.

Pfaudler cars included brine coils to cool the car at the creamery,

and an electric stirring mechanism to keep butterfat distributed through the milk

and minimize deposition on the interior of the tank.

Stirring also helped maintain a uniform temperature throughout the tank.

https://en.wikipedia.org/wiki/Milk_car#/media/File:Pfe722.jpg

Cans of raw milk were transported in insulated cars with high-speed trucks.

- Part #: Ath-11621 - Fairfield Farms - Road #: 103 - Pfaudler 40' Milk Car

11621_Fairfield.JPG

-

Google Books Result - Guernsey Breeders Journal July 1918

Google Book Result - Hoard's Dairyman August 2, 1918 found searching for Fairfield Farms "Famous for Babies"

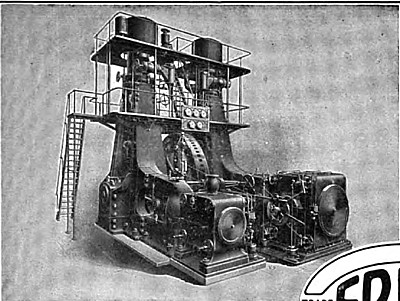

Steam - Ammonia Refrigeration / Frick

- Wiki on steam Ice plants

https://en.wikisource.org/wiki/Popular_Science_Monthly/Volume_39/May_1891/Ice-Making_and_Machine_Refrigeration

Popular Science Monthly/Volume 39/May 1891/Ice-Making and Machine Refrigeration

ICE-MAKING AND MACHINE REFRIGERATION. By FREDERIK A. FERNALD.

THE manufacture of ice now bids fair to become a regular industry in temperate as well as in tropical climates.

Pioneer work in this field was done more than sixty years ago, but it is only within the last ten years that the groping attempts of the early inventors

have developed into processes sufficiently economical to make the artificial production of ice a commercial success.

Artificial ice has been made in tropical countries and in our Southern cities for many years,

but the industry has been greatly extended in this country by the two successive mild winters of 1888-'89 and 1889-'90.

It has now gained a foothold even in our Northern States, while in the South comparatively small towns have their ice factories.

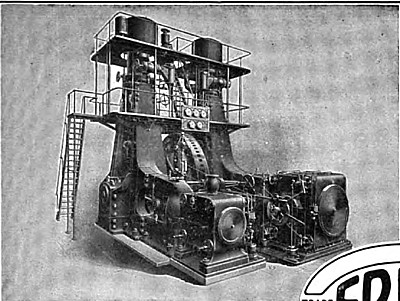

- Fairfield Farms Dairy in Baltimore added 15ton Waynesboro Frick unit at it's plant according to ICE and REFRIGERATION Monthly 1919

History of the Frick Company Copyright 1952

History of the Frick Company (full text)

At seventeen George (Frick) was apprenticed to Martin Kendig, a millwright living at Ringgold, Md., a few miles south of Waynesboro.

In 1848 George hrmself began manufacturing gram cleaners and horsepowers in a weaving mill at Quincy.

There, two years later, he constructed his first steam engine; this was mounted on a wooden frame and delivered two horsepower.

In December of 1849 George had married Fredenca Oppenlander. That same year he started the advertising program which is still continued.

In 1851 or '52 he built a shop on a farm near Ringgold, and in 1853 established Frick Company.

http://www.johnsoncontrols.com/buildings/refrigeration/industrial-refrigeration/frick-refrigeration

http://articles.herald-mail.com/2003-09-28/news/25116401_1_steam-threshers-sawmill

100 Cumberland Valley Ave. The Frick Co. was bought in 1988 by York International.

Although Frick is part of the corporate name, local residents always have and probably always will simply call it "Frick," as in, "He works at Frick."

- ammonia refrigeration through the years

It was rather unfortunate that the various tables did not agree. The American Society of Refrig-eration Engineers (ASRE) was greatly concerned about this matter.

ASRE petitioned Congress, which authorized the U.S. Bureau of Standards in 1921 to investigate and publish accurate tables for the use of the rapidly growing refrigeration industry.

The U.S. Bureau of Standards published the first property tables in 1923.

Three years later, ASRE published a data book titled Thermodynamic Properties of Refrigerants and Brines.

It carries a note which says that three years of experience with the tables produced by the U.S. Bureau of Standards has proven their accuracy and they will remain accurate tables for all time to come.

I also wish to point out that the production of ammonia from the waste of slaughtering continued until the mid-1920s.

The first cylinders of ammonia that I handled in 1920 bore the name “Armour and Company.”

About the same time, the magazine Ice and Refrigeration had an article saying that a low-cost material had been discovered which would enable the synthetic production of ammonia.

Sure enough, from the mid-1920s on, ammonia cylinders no longer bore the name “Armour and Company.”

Instead, other companies that put NH3 together synthetically now marked the cylinders.

Creamery Equipment

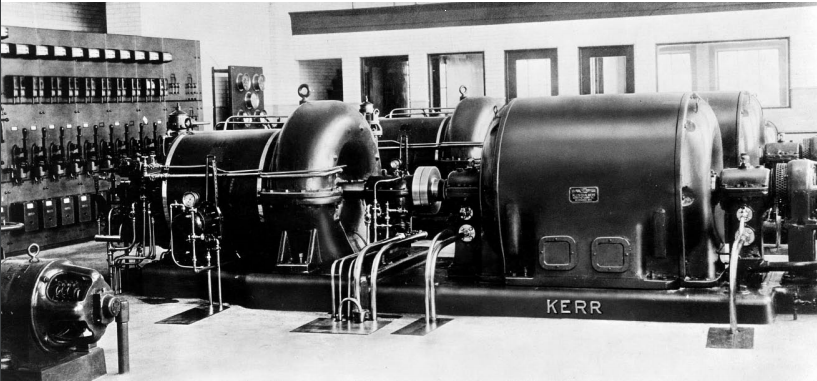

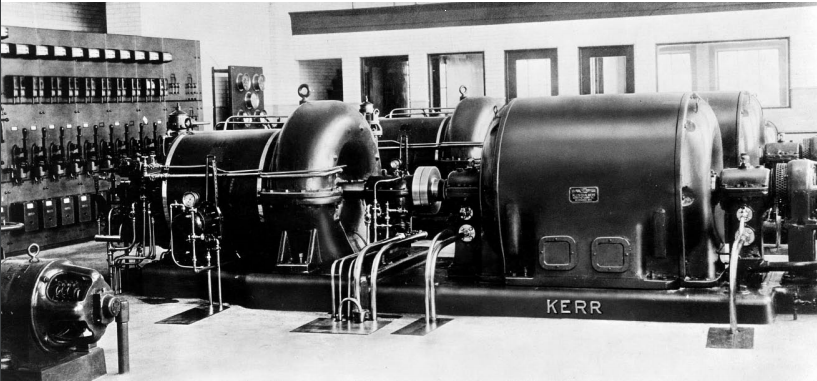

- 1923 Kerr Turbine Powered Electrical Generator

- Skaneateles Historical Society Creamery

- The Melrose Area Historical Society

- The Melrose Area Historical Society Creamery post on Facebook

- The STIRLING CREAMERY

- Oran Cooperative Creamery

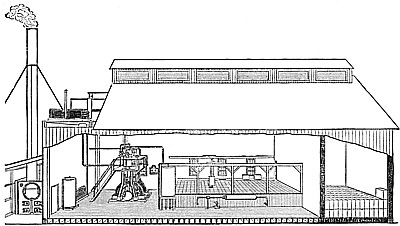

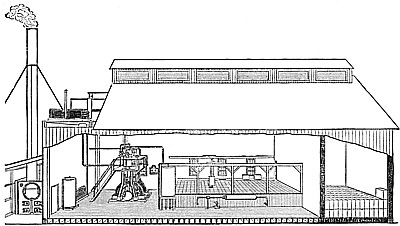

Energy for the creamery in those days was generated by steam, created in a large boiler furnace.

The furnace powered a line shaft that ran the full length of the building,

which in turn operated the separator, butter churn, and several additional pieces of creamery equipment.

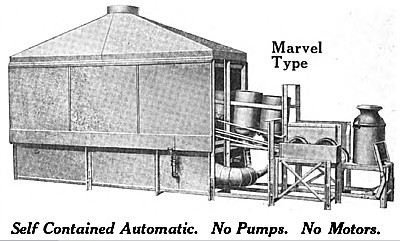

- January 1921 Creamery and Milk Plant Montly Advertisement

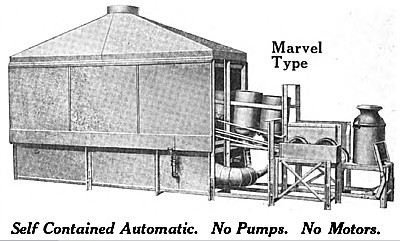

Paulson Co Marvel can washer

- John Ladd Bottle Washer January 1921 Creamery and Milk Plant Montly Advertisement

Would have most likely have been in Baltimore not Detour

- November_1919_Technical_products_Ad_Page_1.png

TP-557. Complete 30 Ton Plant. York vertical single acting belt driven machine 12 1/2" X 18", tank 56' X 18' X 40" with 382 standard 300 lb. ice cans 11 1/2" X 22 1/2" X 45".

- https://books.google.com/books?id=P-0iAQAAMAAJ&q=fairfield+farms+detour&dq=fairfield+farms+detour&hl=en&sa=X&ved=0ahUKEwiW1uvyvYzXAhWGz4MKHbT7CQQQ6AEITDAI

Link has the following text:

Detour. - The Fairfield Farms Dairy Co. has added to its

equipment a 30-ton refrigerating machine, direct connected to a

vertical, enclosed, piston, valve engine, including condensing

side and bleeder, atmospheric, ammonia condensers, also a 4-ton,

flooded, freezing system, and considerable direct expansion piping

for freezer room: furnished by York Mfg. Co.

- Richard Wilhide 10-12-2014 holding ice can

07-16-2016 Richard back and I talked to him about thier farm and the detour dairy

garage for powdered whey was 2 8' diameter stam rollers about that far apart that they'd pour the whey into

Wilhides got power in 1929, dairy built in 1924

dairy shut down in last weeks of 1958, Wilhides got their milk tank weeks before

their silo to right of barn that's gone now built in 1941

Tommy Waverly knows Detour history he grew up behind freight station by mill

1868 milk trains started to run milk to fairfield dairy in Baltimore

farmers would drop off cans off milk at milk stations/platforms and the train would take them to Baltimore and bring the cans back(next day?)

all milk shipments from dairy were by truck

dairy had power from 3 different directions to keep operation going if 1 direction went down

they had thousands of gallons of holding tanks on main floor

the ice vat Richard has is one from the ice plant part of the dairy

Pat/Dan? Wilhide hangs out at store with Tommy

farmers didn't always get paid for the milk they shipped and that's when the coops got started

Tommy is the one that told Richard about the locomotive running the dairy the one day and Richard kind of remebers it

in 1929 the railroad started closing milk stations along the route which were at 3 mile intervals

Richard said the farm put in a free/loafing shed behind the silo in 194? and the dairy went in the other side

and when they were filling silo they had the fence off the cows from crossing and they hadn't thouht ahead but they saw the shed in hoards dairyman and built it from those plans

the original is out in Wisconsin? and Richard got to see it

also talked about no-till starting for them in 1971 and also before that Willard chemical coming up with liquid fertilizer and no one thought that or the no-til would work like it did in other places

Kentucky came up with genetic corn and before that his ddad just picked the best ears from the crop to plant with next year

when milk tanks were going in they all shared each others while theirs were being put in

they were mandated to be put in

there were always railcars parked along side the dairy unloading supplies kind of like KFI they had 2 days to unload them

silo was attempt for summer feeding for the cows that they relied on pasture for before but pasture not always enough and then they's dip into hay

his dad went to meetings and all learning crop rotation etc trying to get the most out of the land

alos this was when the corn crops started and they started with 40" rows and went to 30"

some corn engineered to deal with 15" row but 30" is the best use of land otherwise

- The Butter Industry: Prepared for the Use of Creameries, Dairy - https://books.google.com/books?id=9jQuAAAAYAAJ - Otto Frederick Hunziker - 1920 - Butter

page 29 table 2 number of creameries by state 1914

page 31 Chapter 11 Creamery Organizations, Construction and Equipment

pages 32-35 explain mutual vs joint creamery co-op

pages 36-45 explain construction of a creamery

36 The small local creamery depends for its main supply of milk or cream on a very limited localized territory must obviously be located as near that supply as possible.

A large centralized plant whose supply territory covers wide area, and that recieves the great bulk of its raw material by rail, is compelled to give first consideration to a suitable railway.

The creamery large or small needs a plentiful supply of clean, pure water, free from pollution with organic matter, and objectionable minerals such as iron and sulpher.

37 The disposal of creamery waste is exceedly important. Unless this is provided for by the municipal sewerage system,

a creek or river with running water throughout the year, the creamery resorts to expensive unsatisfactory septic tanks.

If fortunate enough to have sewer install sediment tanks large enought to trap a day's run to trap solids or lose sewer priviledges.(discharge tap on bottom, solids float)

40 locate window high to keep flys away from product. Lots of ventilation.

pages 46-59 explain buying milk and cream

page 53 has figure 1 showing arrangment of cream station

pages 60-67 explain care of milk and cream on farm

page 61 refers to USDA Farmers Bulletin 610 describing crop rotation and weed control

page 63 has figure 2 showing cream separator bowls

page 65 heat conductivity of water is 21 times as great as that of air

page 66 has figure 4 showing practical cream cooling tank Courtesty of Independant Silo Company

pages 68-?? explain The separation of Milk

pages 71-89 centrigual separation

page 72 has table 4 centrifugal seperation speeds

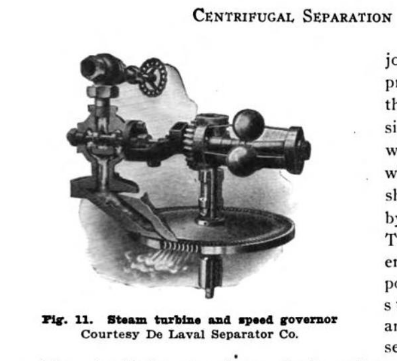

page 73 has figure 5 De Laval centrifugal Cream Seperator

page 85 has figure 11 De Laval Steam turbine and governor

pages 90-101 skimming efficiency of the separator

pages 102-114 conditions affection richness of cream

Condensed Milk and Milk Powder - https://books.google.com/books?id=dPQ1AQAAIAAJ - Otto Frederick Hunziker - 1920 - Condensed Milk

Patent Can washing machine - Paulson, Walter H (Publication Date:12/16/1947,Filing Date:04/10/1941) patent PDF

Created: 11-03-2017 09:53AM

Modified: 11-03-2017 11:56AM

Last Update: